Our Story

The SnowEx® brand is for fearless and driven contractors, the ones who are ready to take charge, build a business, and make a name for themselves. Our gear isn’t just equipment; it’s a tool for empowerment. It’s for those who embrace the grind, value efficiency, and demand the best. SnowEx is built for those who take their hustle seriously.

HISTORY OF SALT SPREADERS TO FULL LINE

Since 1997, SnowEx has established a tradition of innovation, introducing productive and popular snow and ice control products. Headquartered in a state-of-the-art facility in Madison Heights, Michigan, SnowEx offers an extensive line of salt and/or sand spreaders and liquid brine sprayers. In 2015, the product portfolio expanded to include a full line of commercial snowplows.

While we design our gear for maximum uptime and minimal maintenance, we stand behind every hopper, spreader, sprayer, and plow with a premier warranty and a dedicated support team. We are continuously sharing our expertise to help the industry adopt smarter, more effective practices that keep our communities thriving.

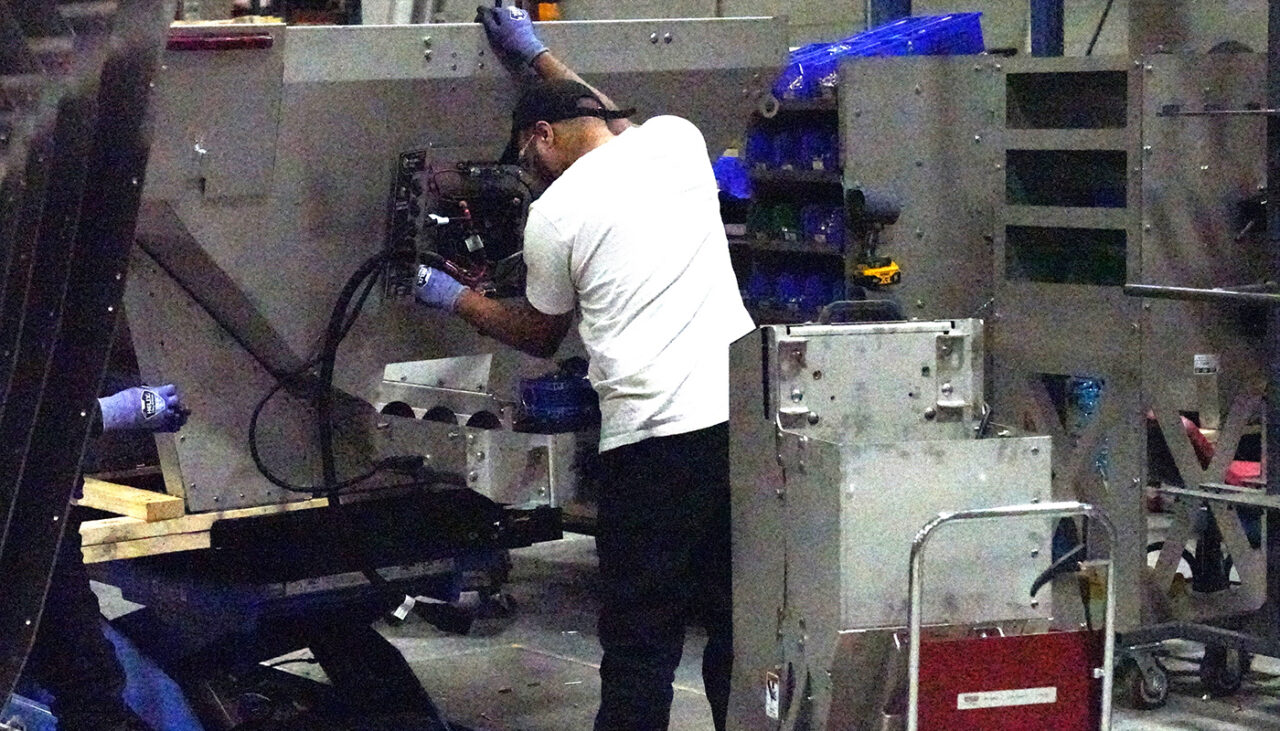

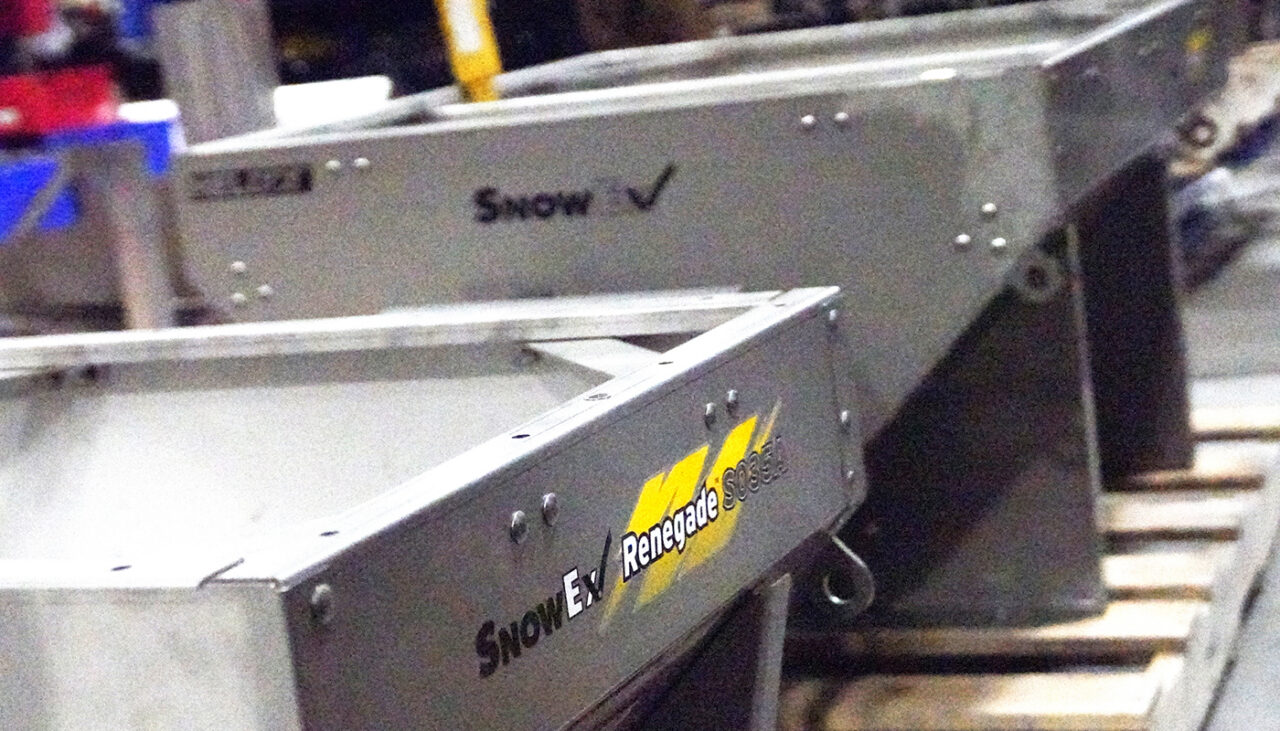

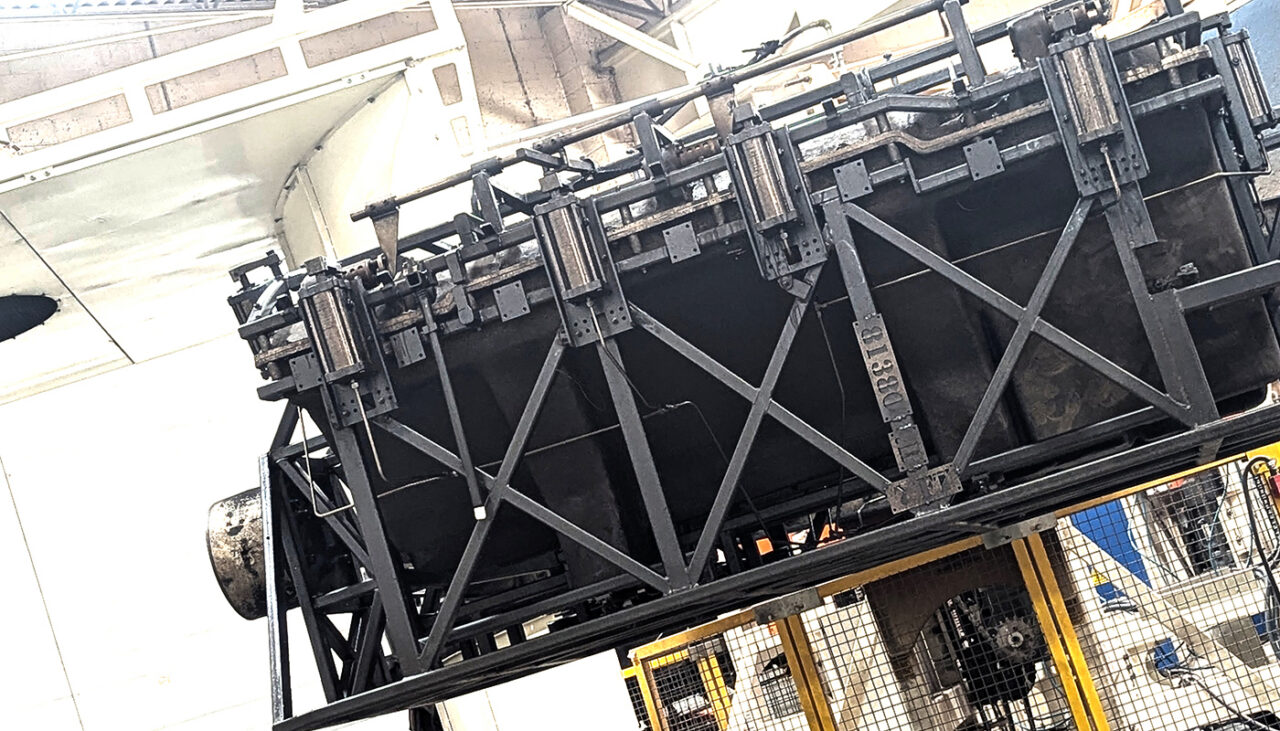

HOW A SPREADER IS MADE

Check out the behind-the-scenes footage of our poly hoppers manufacturing process from concept to completion.

WHY CHOOSE SNOWEX?

TRIPLE THREAT FULLY EXPLAINED

Choose to pre-wet granular material or apply direct liquid by adding a liquid kit (pre-wet tank, pump, and sprayer) and upgrade your setup to a triple threat.

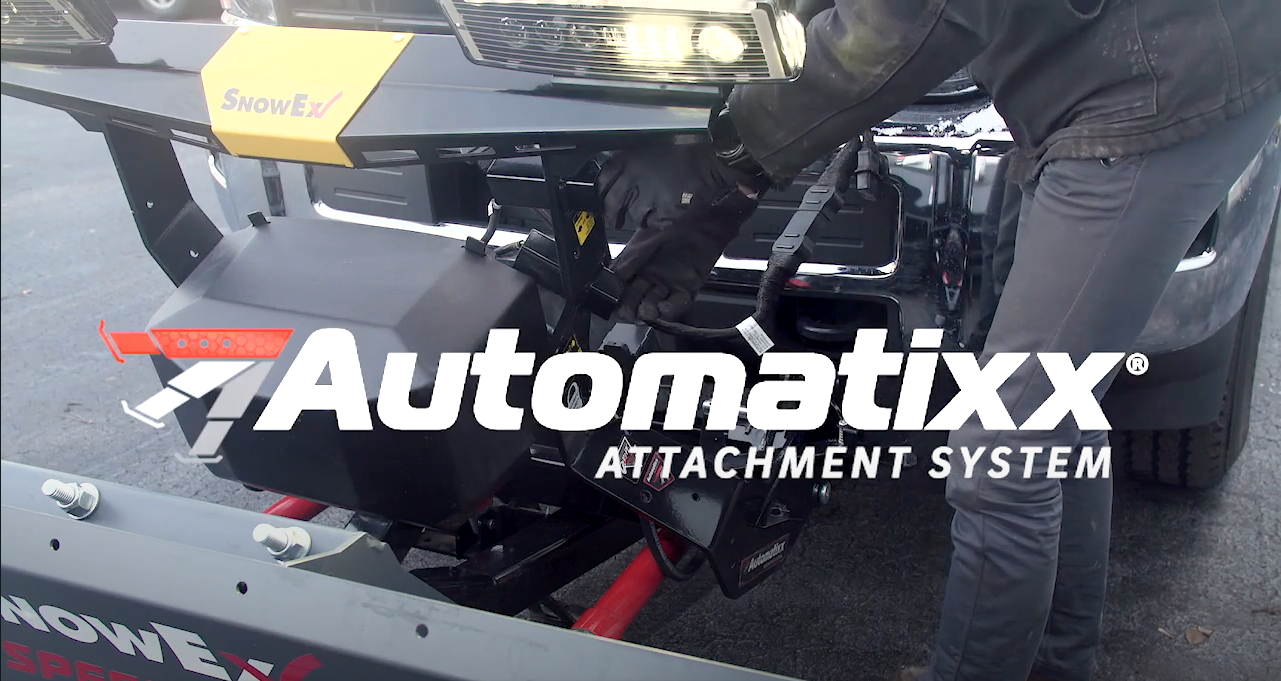

EXCLUSIVE AUTOMATIXX® ATTACHMENT SYSTEM

Hook up your plow in just a few quick and easy steps, from the comfort of your cab. This snowplow attachment system isn’t just fast, it’s automatic.

SCRAPE MAXX™ DOWN-FORCE

STANDARD on all truck plows, providing downward force to bust through hard pack and maximize to-the-pavement scraping performance.

A DOUGLAS DYNAMICS BRAND

SnowEx is proud to be a part of Douglas Dynamics, North America’s premier manufacturer and upfitter of commercial vehicle attachments and equipment. Innovating products for more than 75 years, that enables contractors to perform their jobs more efficiently and effectively and allows businesses to increase profitability.

MEET TAYLOR, ROTOMOLDING EXPERT

Taylor, our Plastics Project Engineer at Madison Heights, takes us inside the rotomolding process where science meets art to shape our spreaders.

LEARN MORE

←

MEET DANNY, SHIPPING SUPERVISOR

With 7 years on the team and a strong work ethic that doesn’t quit, Danny Bozek shares what drives him both on the job and out in the field plowing.

→